Seal Once

Shields concrete & masonry from water damage & decay. Also protects wood from weathering, scuffs and scratches.

Penetrates below the surface to protect against water damage from the inside-out.

Deeply penetrates the surface of wood to protect and stabilize against water damage and decay.

Preserve and enhances the natural beauty of wood while protecting it from harmful UV rays.

Interested with any of the SEAL-ONCE product?

Performance Guarantee

LIMITED LIABILITY: In the event SEAL-ONCE® NANO, NANO+POLYTM, MARINE, EXOTIC, Multi-Surface Concentrate or SEAL ENDS ONCE®, when used according to the product instructions, fails to prevent long-standing water accumulation below a wood or concrete/masonry surface for six (6) years on horizontal surfaces and ten (10) years on vertical surfaces, U.C Coatings, LLC, at its option, shall either replace the product or refund the purchase price.

U.C Coatings, LLC shall have no liability for any other damages or labor costs of any kind, whether direct, incidental, consequential, punitive, or otherwise, for any defect in its products. U.C Coatings, LLC’s liability and warranties cannot be modified or extended by its manufacturer’s representatives, distributors, or dealers of U.C Coatings, LLC products.

Frequently Asked Questions

Common Questions

What kinds of surfaces can I use SEAL-ONCE products on?

SEAL-ONCE products can be used on wood, concrete or masonry. This includes hardwood, softwood, pressure-treated wood, exotic wood, wood siding, log homes, cedar shakes and wood decking. Our products can also be applied to stucco, clay tiles, paver blocks, bricks, poured and stamped concrete, grout and mortar.

What is the difference between SEAL-ONCE NANO, NANO+POLY and POLY?

SEAL-ONCE NANO is a non-film forming, deep-penetrating, water based formula that creates a flexible, breathable barrier to protect wood against damage caused by water ingress. It is ideal for vertical surfaces and areas that will not be subjected to a high level of wear and tear.

SEAL-ONCE NANO+POLY combines our proprietary nanotechnology formula with the strength of polyurethane to provide 360° of protection for wood, concrete and masonry. It is ideal for high traffic applications such as decks and patios.

SEAL-ONCE POLY forms a durable, flexible barrier on the surface that shields wood, concrete and masonry from water damage, abrasion and harmful UV rays. It is ideal for projects where there will not be a lot of foot traffic but where a high gloss, uniform finish is desired.

How should I store my unused SEAL-ONCE product? What is the shelf life of SEAL-ONCE products?

To obtain the maximum life out of your SEAL-ONCE product, it should be stored much like paint in a tightly sealed container at room temperature. As long as they remain unopened, SEAL-ONCE NANO has a shelf life of 3 years; SEAL-ONCE NANO+POLY has a shelf life of 2 years; and SEAL-ONCE POLY has a shelf life of 18 months.

How long does it take for SEAL-ONCE to fully cure?

SEAL-ONCE NANO, MARINE, SEAL ENDS ONCE and Multi-Surface Concentrate are fully cured within 12-24 hours, depending on temperature and humidity. SEAL-ONCE NANO+POLY, EXOTIC and POLY are fully cured within 24-48 hours, depending on temperature and humidity.

How long do your products need to dry before it rains?

We recommend waiting until it will not rain within the full cure time for the product you are applying. Please refer to the appropriate Technical Data Sheet for cure times.

How does SEAL-ONCE® NANO Penetrating Wood Sealer work?

SEAL-ONCE NANO deeply penetrates the wood surface by utilizing proprietary nanotechnology to create a flexible, breathable barrier that prevents water damage and decay and allows water vapor to escape. It is non-film forming and will not peel.

Do SEAL-ONCE products provide UV protection?

Yes, all of the SEAL-ONCE formulas provide UV protection. The UV protection provided by SEAL-ONCE NANO is enhanced by adding a Semi-Transparent Tint. NANO + POLY has a higher level of UV protection with the addition of UV blockers. POLY provides the highest level of UV protection.

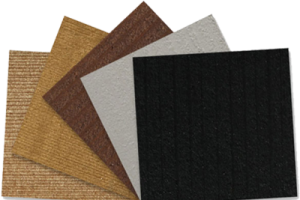

Do SEAL-ONCE products come already tinted or do I need to add color myself?

SEAL-ONCE wood sealers are compatible with our Semi-Transparent Wood Tints. These tints and stains are sold separately and are added in a 1:1 ratio; one tint bottle per one gallon of SEAL-ONCE. The colors can be added to SEAL-ONCE NANO, NANO+POLY, EXOTIC and MARINE. When using Multi-Surface Concentrate, color can be added for wood applications after the base product has been properly diluted.

The colors cannot be added to SEAL-ONCE POLY or SEAL ENDS ONCE.

Can all SEAL-ONCE products be used for interior and exterior applications?

Yes, SEAL-ONCE products are safe for both interior and exterior use.

Are SEAL-ONCE products eco-friendly?

Yes, SEAL-ONCE products are water based, do not contain any harmful chemicals or toxins and are ultra-low VOC. Our products can be safely applied and will not harm pets, plants, people and marine life. Additionally, our products do not require special personal protective equipment (PPE) or disposal methods and can easily be cleaned up using soap and water.

Product Application Questions

How do I prepare the surface for the application of SEAL-ONCE products?

SEAL-ONCE must be applied to bare wood. If the surface has been previously coated with another stain or sealer, that product must be removed. Common practices for preparing your wood project include power washing, using a cleaner such as our All Wood Cleaner, sanding the surface or using a stripper to remove all previous stains and coatings Ensure all surfaces have been properly cleaned by using the appropriate SEAL-ONCE cleaner (All Wood Cleaner or Concrete/Masonry Cleaner). After cleaning, rinse the surface with water and allow to dry completely. Once the surface has been cleaned and the old coating has been removed, SEAL-ONCE products can be applied, according to the package instructions.

Do you recommend covering all materials and surfaces that are not being sealed with SEAL-ONCE products?

Yes, we recommend covering all surrounding materials and surfaces, as well as wiping down or removing all areas impacted by over-spray while still wet. While all SEAL-ONCE products are eco-friendly and will not harm the surrounding landscaping, it is advised that you cover any adjacent walls or materials that are not recommended for coating with SEAL-ONCE, especially if you are using one of our Semi-Transparent Tints.

Do I need special equipment to apply SEAL-ONCE products?

No, you do not need special equipment. SEAL-ONCE products can be applied using a synthetic brush or stain pad. For faster application, a pump sprayer with a 0.015-0.017 tip can be used. Additional application information is listed on our Technical Data Sheets, which can be found on our Data Sheets & Guides page.

At what temperatures can I apply SEAL-ONCE products?

The temperature range for applying SEAL-ONCE NANO, MARINE, SEAL ENDS ONCE and Multi-Surface Concentrate is 45°F (7.22°C) to 95°F (35°C). The temperature range for applying SEAL-ONCE NANO+POLY, EXOTIC and POLY is 50°F (10°C) to 95°F (35°C). These temperature ranges apply to both surface and air temperature for wood and concrete.

SEAL-ONCE NANO GUARD Questions

Will tinted SEAL-ONCE NANO leave dark streaks or overlap marks?

No, tinted SEAL-ONCE NANO will not leave streaks when applied properly. When following our instructions for applying two (2) coats “wet on damp,” the second coat will blend evenly into the first.

How long do I have to wait before applying a second coat of SEAL-ONCE NANO?

The second coat of SEAL-ONCE NANO can be applied as soon as the first coat has penetrated but is still damp. The second coat must be applied within one hour of applying the first coat.

SEAL-ONCE ACRYLIC POLY Questions

Do I need to sand the surface between coats of SEAL-ONCE POLY?

If the proper application procedures are followed, it is not necessary to sand the surface between coats of SEAL-ONCE POLY. If the first coat has been allowed to cure for more than 24 hours, lightly sand the surface with 220 grit sandpaper. Remove all dust after sanding to ensure a clean, debris-free surface prior to applying the second coat of SEAL-ONCE POLY.

SEAL-ONCE NANO GUARD PLUS POLY Questions

How long do I have to wait before applying a second coat of SEAL-ONCE NANO+POLY?

The second coat of SEAL-ONCE NANO + POLY can be applied as soon as the first coat has penetrated but is still damp. The second coat must be applied within one hour of applying the first coat.

Seal-Once Semi-Transparent Tints Questions

Why doesn’t the color I purchased match the color displayed on your website?

All of our tints and stains are semi-transparent and allow the natural color and grain of the wood to show through. The color charts on our website have been created using two coats of our tinted SEAL-ONCE products on red cedar. If you are coating a different material, you may see different results. Using more than two coats will also result in a darker, more saturated appearance. The color may also vary depending on which formula you are using as the colors may appear darker or more saturated in some formulas.

I can’t decide between colors. How can I be sure I choose the right color for my project?

We offer 4oz pre-mixed bottles of all of our semi-transparent tints for testing on the material you are coating. Samples can be purchased in our webstore.

Can I take other tints, stains or pigment colors from other manufacturers and mix them into any SEAL-ONCE product?

No, only the SEAL-ONCE® semi-transparent tints have been specially formulated for our products. Other colors or pigments may alter the effectiveness of our products.

Substrate-Specific Questions – Concrete

Do SEAL-ONCE products prevent efflorescence?

Yes, SEAL-ONCE NANO+POLY and POLY prevent efflorescence, which occurs when water penetrates the concrete and leaches out naturally-occurring salts, creating undesirable white stains on the concrete. Efflorescence must be removed prior to applying SEAL-ONCE, if it is already present on the surface.

Can SEAL-ONCE products be applied to green concrete?

Yes, SEAL-ONCE NANO+POLY and NPW can be applied to green concrete after nine days, with the exception of SEAL-ONCE POLY. SEAL-ONCE POLY can only be applied to concrete after the full 28 day cure.

Substrate-Specific Questions – Wood

Why do I need to wait 3 to 6 months before applying SEAL-ONCE to pressure treated lumber?

Pressure treated wood is created using chemicals and other materials that need to properly cure prior to applying a waterproofing sealer or other coating. If a sealer or coating is applied to pressure treated wood before it has cured, it can result in peeling, cracking, bubbling and other adhesion problems. In the case of SEAL-ONCE products, if the they are applied too soon, the chemicals in the wood will prevent penetration, which will inhibit the product’s ability to protect the wood. The best way to determine if pressure treated wood has cured, and is ready for SEAL-ONCE products to be applied, is to sprinkle water on the surface to see if it soaks in or pools. If the water soaks in, the wood has cured and is ready for SEAL-ONCE to be applied. If it pools or forms droplets, you need to wait longer before applying SEAL-ONCE.

Can SEAL-ONCE products be applied to green or freshly cut wood?

SEAL-ONCE NANO, MARINE, EXOTIC and NANO+POLY can be applied to freshly cut wood because they create a breathable barrier that allows water vapor to escape as the wood ages. We do not recommend using SEAL-ONCE POLY on freshly cut wood as it creates a surface coating and is not breathable.

Do you need assistance in choosing the right wood and cement sealer for you?

We can help you from selecting the correct product you need in your project

from its professional engineering services.

Do you need assistance in choosing the right wood and cement sealer for you?

We can help you from selecting the correct product you need in your project from its professional engineering services.